Controlled Atmosphere Heat Treating

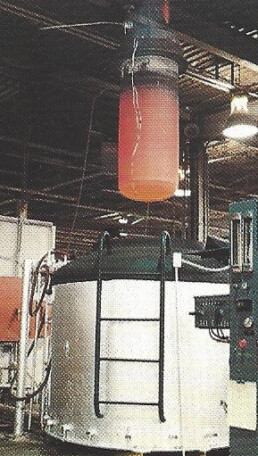

Using our environmentally-compatible retort and atmosphere furnaces, we can control hydrogen, nitrogen, argon, inert gases, and other customer-specified atmospheres. These furnaces are used for annealing, hardening, tempering, normalizing, and stress relieving.

Hy-Vac’s stress relieving furnaces reduce stress resulting from forming, rolling, machining, or welding — first heating components to specified temperature levels, then cooling them at slower rates. This procedure can be incorporated into the engineering process for large or intricate parts.

Below are the most commonly processed materials and specifications. Please contact us for inquiries about any not featured on this list.

Materials & Capabilities

Annealing

Carbon steel

Castings

Normalizing

Carbon steel

Castings

Precipitation Hardening

17-4PH, 17-7PH, 15-5PH, 15-7PH

Inc. 718 and Inc. X750

A-286, 13-8PH and Waspaloy

Industry Specifications

AMS-2759 General Steel

AMS-2759/1 Steel

AMS-2759/3 PH Grades

AMS-2774 Nickel and Cobalt alloys

AMS/MIL-H-6875 Steel

AMS-5663 Inc. 718

AMS-2750 Pyrometry

For prime specific specifications, see our prime approval list.

Certifications

Our commitment to quality has made us a trusted supplier for a variety of industrial heat treating services. Hy-Vac Technologies is proud to carry numerous aerospace approvals and accreditations.